Understanding the Value of Foam Control in Industrial Processes

In industrial procedures, foam control is typically a neglected yet essential element that straight influences operational performance and item integrity. The presence of extreme foam can lead to substantial difficulties, including interfered with mixing and lessened response kinetics, which may eventually affect product top quality throughout various industries such as drugs and food production.

The Duty of Foam in Market

Foam plays a significant duty in numerous commercial procedures, influencing both performance and item top quality. In markets such as food and beverage, pharmaceuticals, and petrochemicals, foam can offer both useful and damaging objectives. In the food industry, foam stabilization is vital throughout procedures like whipping lotion or creating beer, where the top quality of foam directly influences customer understanding and item features.

In chemical production, foam can work as an obstacle, preventing the proper blending of reagents, which can bring about incomplete reactions and suboptimal returns. On the other hand, in procedures like flotation in mineral handling, foam is utilized to divide beneficial minerals from waste material, boosting recovery prices.

Additionally, in wastewater therapy, foam formation can indicate the visibility of raw material, working as an essential parameter for procedure monitoring. The capability to control foam is vital for preserving process stability and maximizing operational costs. Understanding the duty of foam in industrial applications permits drivers and engineers to implement effective foam administration methods, ensuring that foam contributes positively to general procedure performance while minimizing its potential downsides.

Usual Obstacles of Foam Development

Many sectors face significant obstacles due to the unintentional development of foam throughout various processes. Foam can interrupt the performance of procedures, bring about increased downtime and higher functional costs. In sectors such as drugs, food and beverage, and wastewater treatment, foam can prevent mixing, decrease item yield, and complicate splitting up procedures.

Additionally, foam can create safety threats by blocking clear presence, which is vital in environments where exact dimensions and tracking are essential. The visibility of foam can likewise lead to devices damages, as excessive pressure accumulation might happen in activators and storage tanks.

Additionally, the demand for regular intervention to handle foam can draw away sources and labor, eventually impacting performance. Environmental laws pose one more challenge, as too much foam can cause non-compliance concerns in effluent discharge, necessitating extra therapy procedures.

Influence On Product Top Quality

In chemical production, foam can prevent reaction kinetics by limiting gas-liquid contact, bring about insufficient responses and reduced returns. This not only influences the efficiency of production but can also lead to low quality output that do not meet regulative requirements or consumer specs.

Moreover, in pharmaceuticals, foam formation during solution processes can introduce air bubbles try this out into sensitive compounds, jeopardizing medicine efficiency and security. Furthermore, foam can cause operational issues such as overflow and tools malfunctions, increasing downtime and upkeep expenses, additionally influencing product quality and consistency.

Techniques for Reliable Foam Control

Addressing the difficulties positioned by foam is vital for keeping product quality throughout numerous industrial sectors. Reliable foam control methods are necessary to alleviate the adverse impacts of foam development, which can interfere with procedures and compromise product integrity.

One of the key methods includes the selection and application of proper antifoaming representatives. These representatives are developed to reduce surface area stress and inhibit bubble development, and their effectiveness can differ based on the specific procedure problems. Regular tracking of foam degrees is essential to ensure timely intervention, permitting drivers to apply antifoaming agents before foam comes to be a substantial concern.

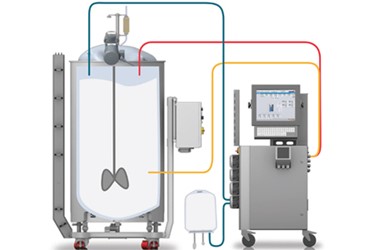

Furthermore, enhancing process parameters such as temperature and agitation can play an essential function in foam monitoring. Decreasing agitation intensity or changing feed prices can lessen foam generation. Implementing mechanical foam control devices, such as foam breakers or defoamers, can also supply reliable options for high-foaming applications.

Educating workers on foam monitoring methods and the relevance of maintaining optimum operating conditions further enhances foam control initiatives. Foam Control. By using a mix of these methods, industries can properly handle foam, making certain functional effectiveness and maintaining the top quality of their products

Future Trends in Foam Administration

How will innovations in modern technology form the future of foam management in industrial procedures? The integration of man-made knowledge (AI) and maker learning will certainly transform foam control strategies, allowing real-time tracking and adaptive reactions to foam development. These technologies can evaluate operational specifications and historic information to forecast foam habits, enabling preemptive procedures that boost process effectiveness.

Additionally, the check here growth of sophisticated foam control agents, including bio-based and ecologically friendly choices, is acquiring traction. These innovations not only reduce foam yet additionally straighten additional hints with sustainability objectives, decreasing the environmental footprint of industrial procedures.

Automation will additionally play a crucial duty, as automated foam control systems can maximize the dosage of defoamers based on real-time dimensions, minimizing waste and enhancing efficiency.

Additionally, the adoption of IoT (Net of Things) tools will certainly assist in smooth communication between tools and foam control systems, making sure an alternative strategy to foam management. (Foam Control)

Final Thought

In final thought, effective foam control is necessary for optimizing commercial processes across numerous markets. Carrying out critical foam monitoring methods, including the use of antifoaming representatives and procedure optimization, mitigates these obstacles.

In the food sector, foam stablizing is important during procedures like whipping lotion or creating beer, where the high quality of foam directly impacts customer perception and item features.

Recognizing the duty of foam in industrial applications allows drivers and engineers to execute effective foam administration techniques, making sure that foam adds favorably to overall process efficiency while minimizing its potential drawbacks.

Regular monitoring of foam degrees is important to make certain prompt intervention, enabling drivers to apply antifoaming agents prior to foam comes to be a considerable issue.

Executing mechanical foam control gadgets, such as foam breakers or defoamers, can additionally offer reliable solutions for high-foaming applications.

The integration of fabricated knowledge (AI) and maker learning will certainly transform foam control methods, allowing real-time tracking and adaptive reactions to foam formation.